DIGITAL CERAMIC MOLDING

cheLA - TaMaCo

In collaboration with: Heidi Jalk

Maria Pia Fatta, Guillaume Jami

2015-2018

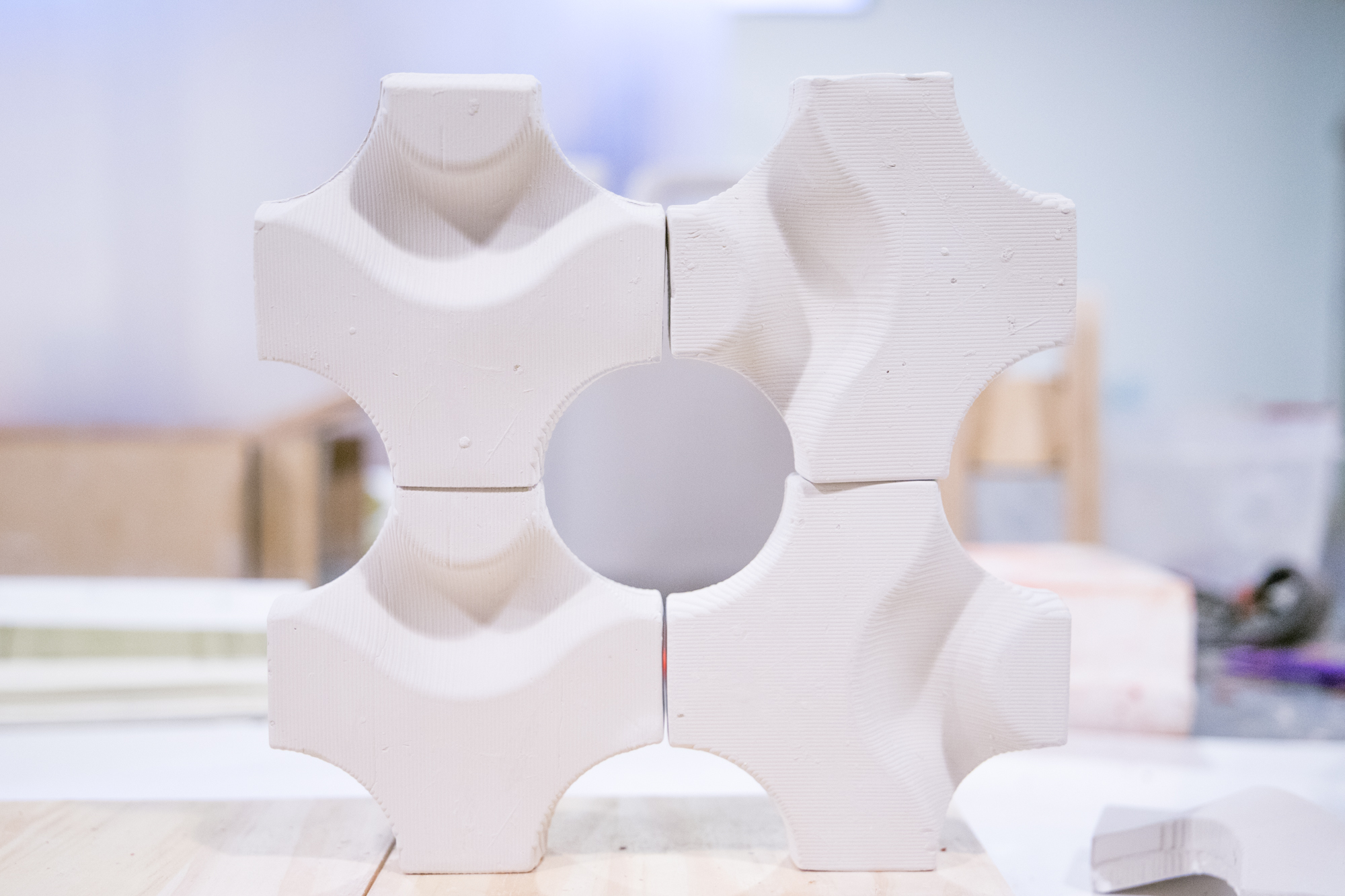

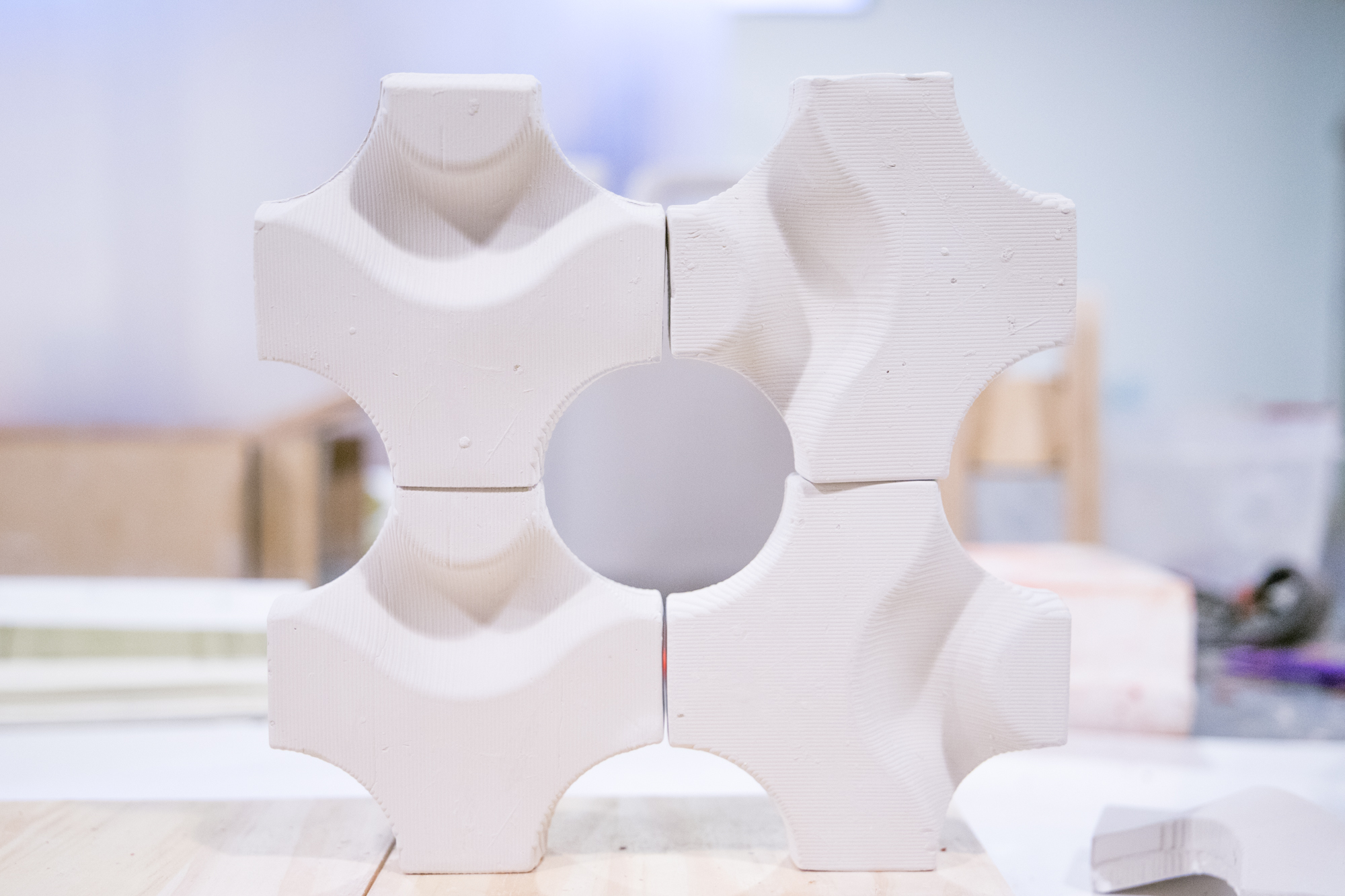

Ceramics is one of the most common and ancient materials, but its forms of production have mostly stayed the same since the 18th century and mass production. It is a very malleable material and allows several production techniques. One of the most common and well-known techniques for the mass production of ceramics is casting in plaster molds.

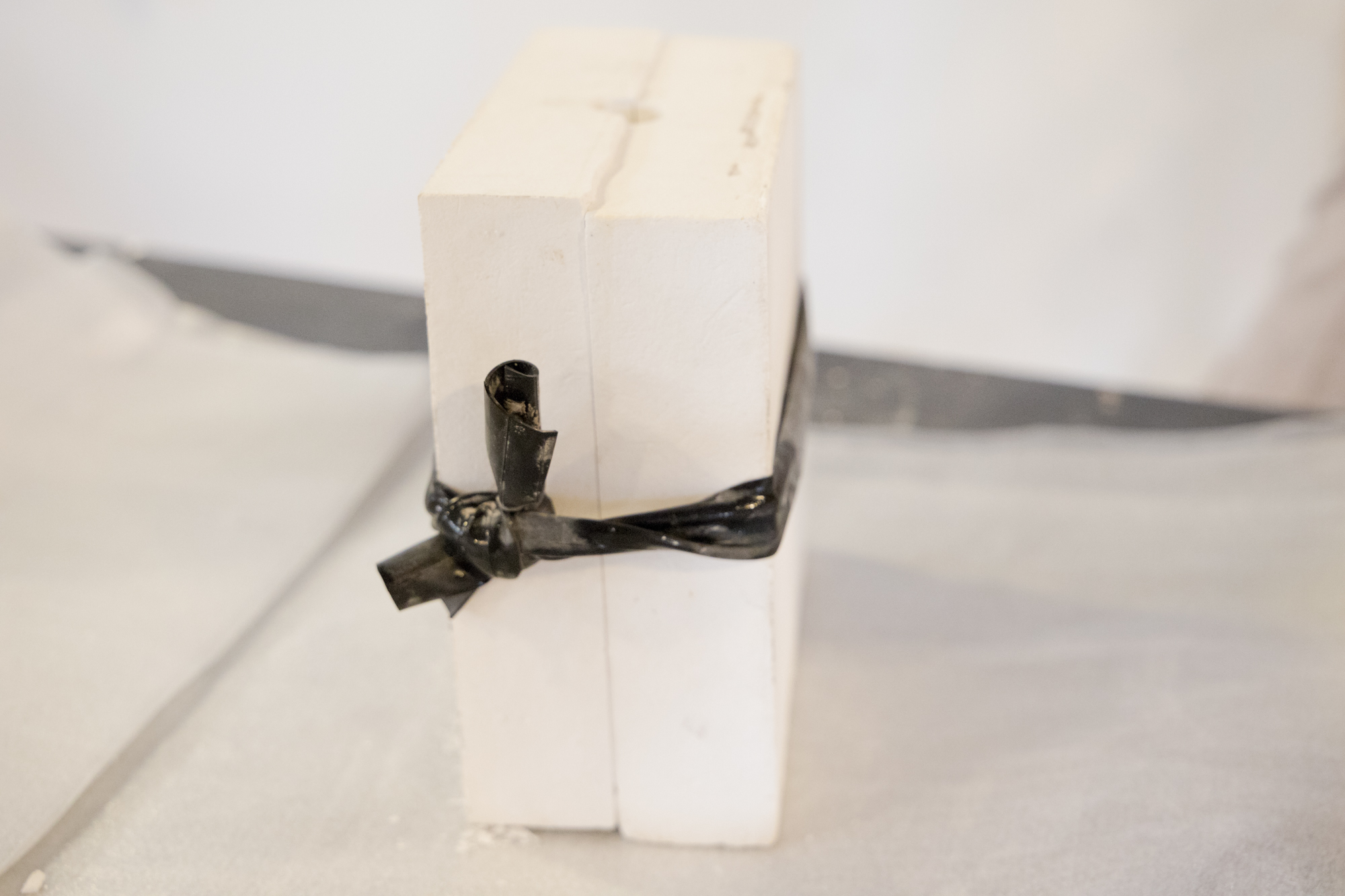

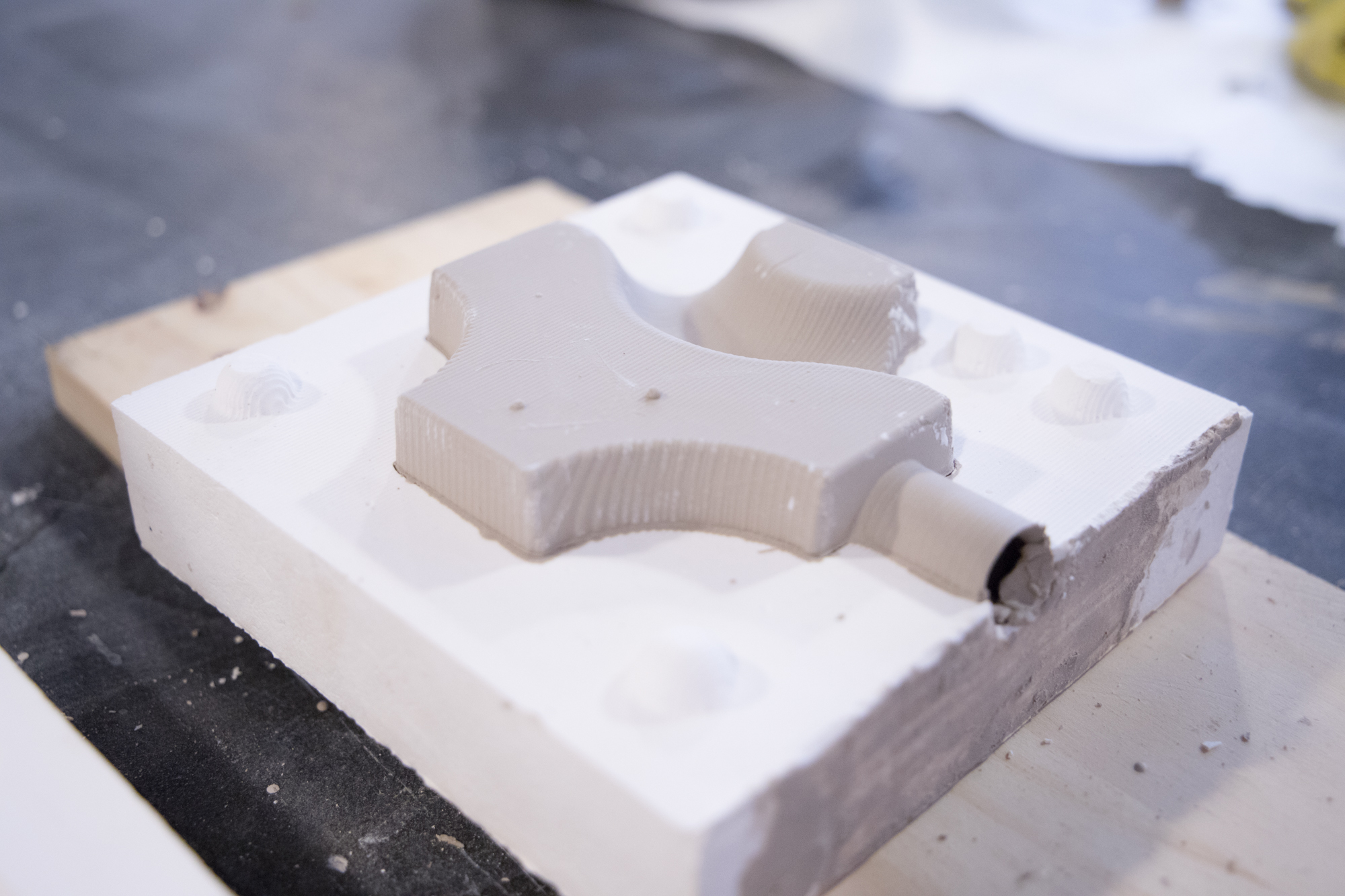

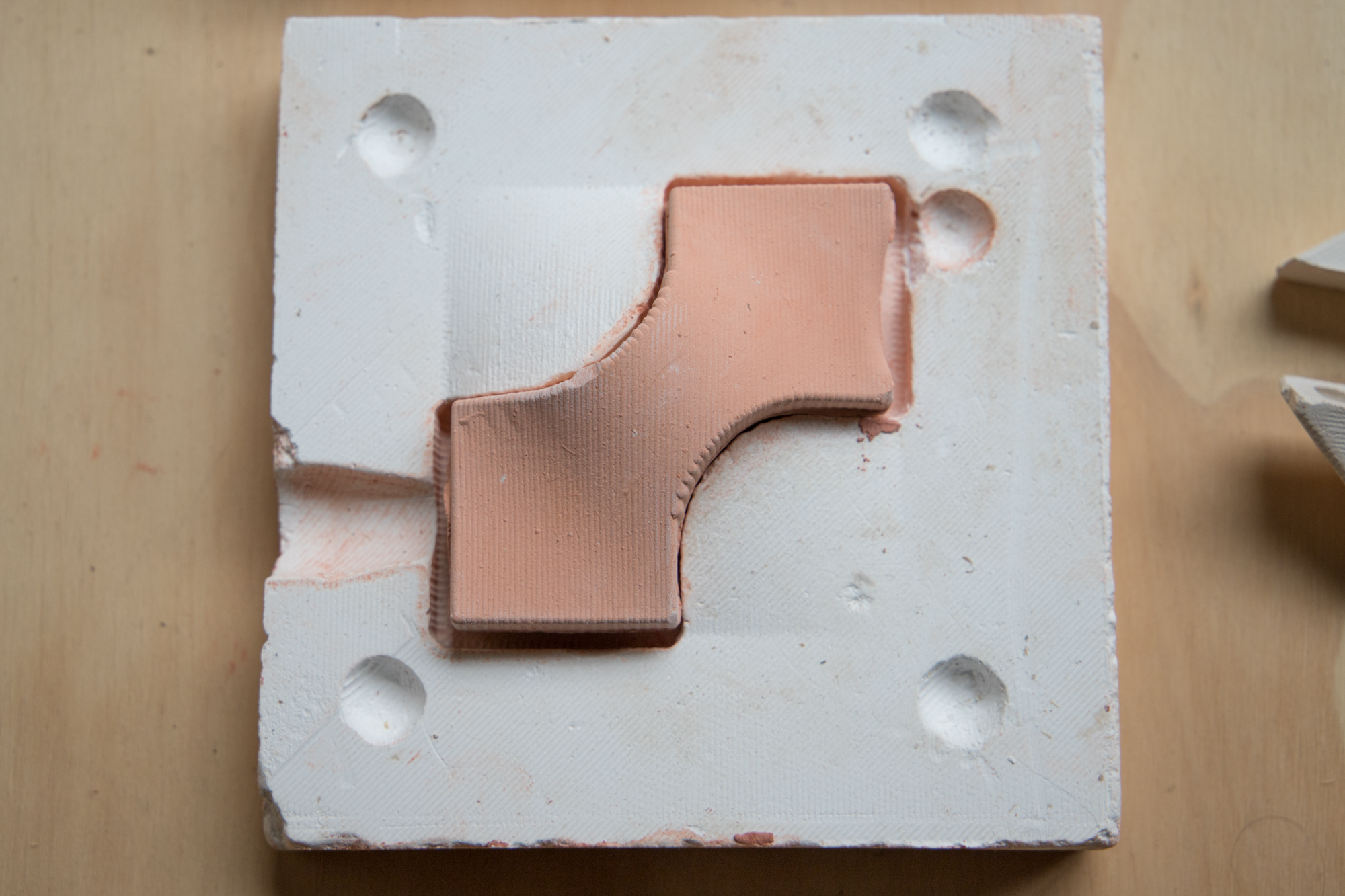

Molds for making ceramics usually have geometrical limitations that derive from the de-molding restrictions, and their manufacture usually depends on a master or company specializing in molding plaster. Digital manufacturing technologies offer solutions to address this problem, bringing the process closer to the designer. In this project, I investigated how plaster molds can be generated using two digital manufacturing methods: additive and subtractive. In the additive method, a 3D print was used to create the base piece, which was then used to generate the plaster mold. In the subtractive process, a plaster cube was milled using a CNC milling machine with the desired geometry. Finally, the casting was done to have the final piece. Both geometries were generated with computer techniques, creating new languages and debates about the means of production used in the age of digital materiality.

sion)

KAPHEND 2025 — Planet Earth